Pile Extraction

The type of piling equipment used for extraction will depend on a few things:

Where noise and vibrations are a concern, for sheet pile extraction, the Still Worker pile press is perfect since it produces virtually none. The pile press is also ideal for use where there is restricted access. This is because the Still Worker can self-travel along the piles and a crane is only required to lift the pile out of the chuck once it has been extracted.

The size and type of pile being extracted is a consideration. For trench sheets or small sheet piles the excavator mounted vibratory hammer would be utilised. For tubes/temporary casings, sheet, timber or concrete piles, a bigger crane suspended vibratory hammer would do the job.

The ground conditions will also help determine which method to use, but it is always best to speak to one of our experts who will be able to recommend the perfect solution for your site.

For the more difficult jobs, where piles are refusing, we are able to supply jetting equipment that loosens the surrounding soil.

Case Studies

Case Study: Vibro Extraction of Concrete Piles

The vibrator was fitted with a special clamp for this application and a snorkel hose connected to the gearbox breather. The client was successful in removing all the obstructing piles with this system.

Case Study: Pulling Power

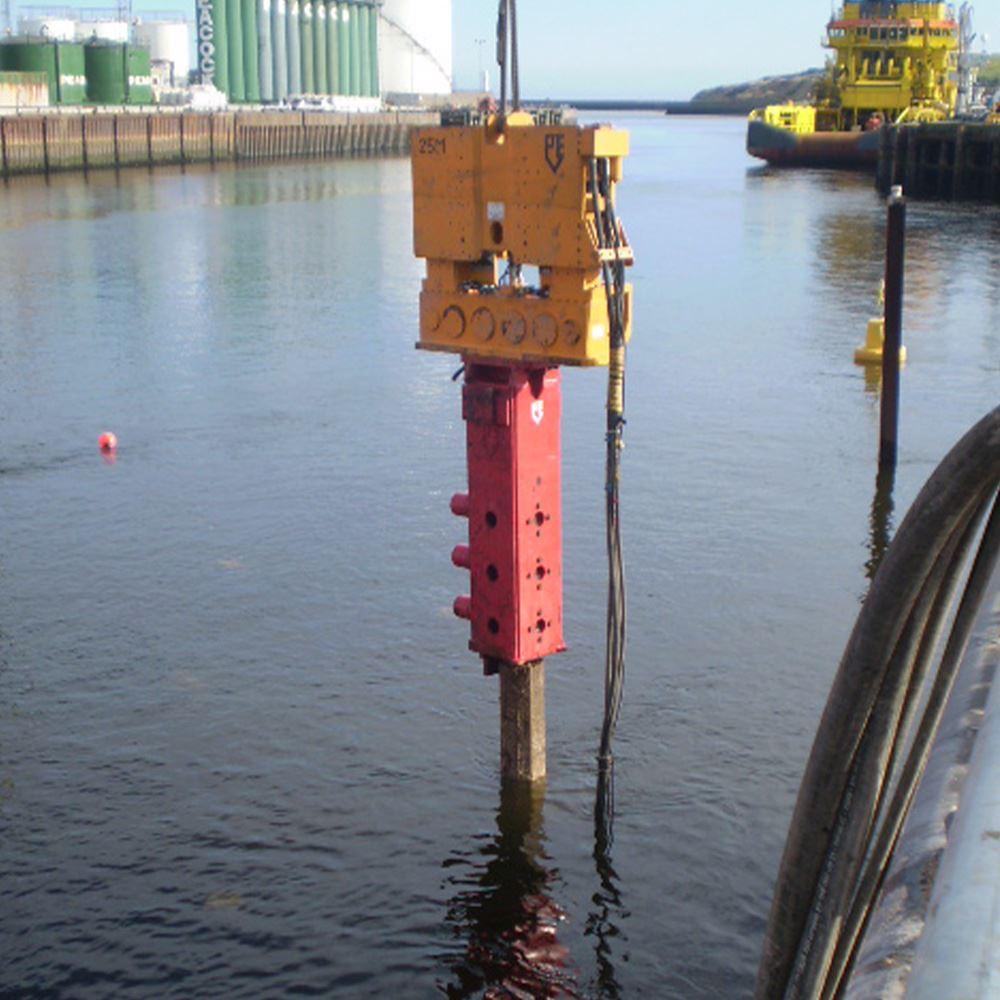

Case Study: Jet Powered Extraction

The suction of the mud proved too much and the piles were refusing. One call to our hire department and our water jetting kit was sent down to assist. It worked a treat and the job was quickly back up and running.

How can we help?

“Contact us today to discuss your piling plant requirements with our expert team.”

Scott