Marine Piling

Adaptable and efficient piling equipment

For all types of marine piling:

For inland waterways, and works such as bank protection or retaining walls, an excavator mounted vibrator can often be used since they are adaptable and efficient piling hammers that can cope with most soils.

For ports, harbours, quays and other coastal work on sea walls, coastal defence, flood alleviation and other larger scale operations there are several options available: a crane suspended vibratory hammer, pile press or a hydraulic hammer – the environment/ground conditions dictates which solution would be suitable.

For offshore piling, for example installing large diameter tubular piles, the crane suspended vibratory hammers or hydraulic hammers are ideal.

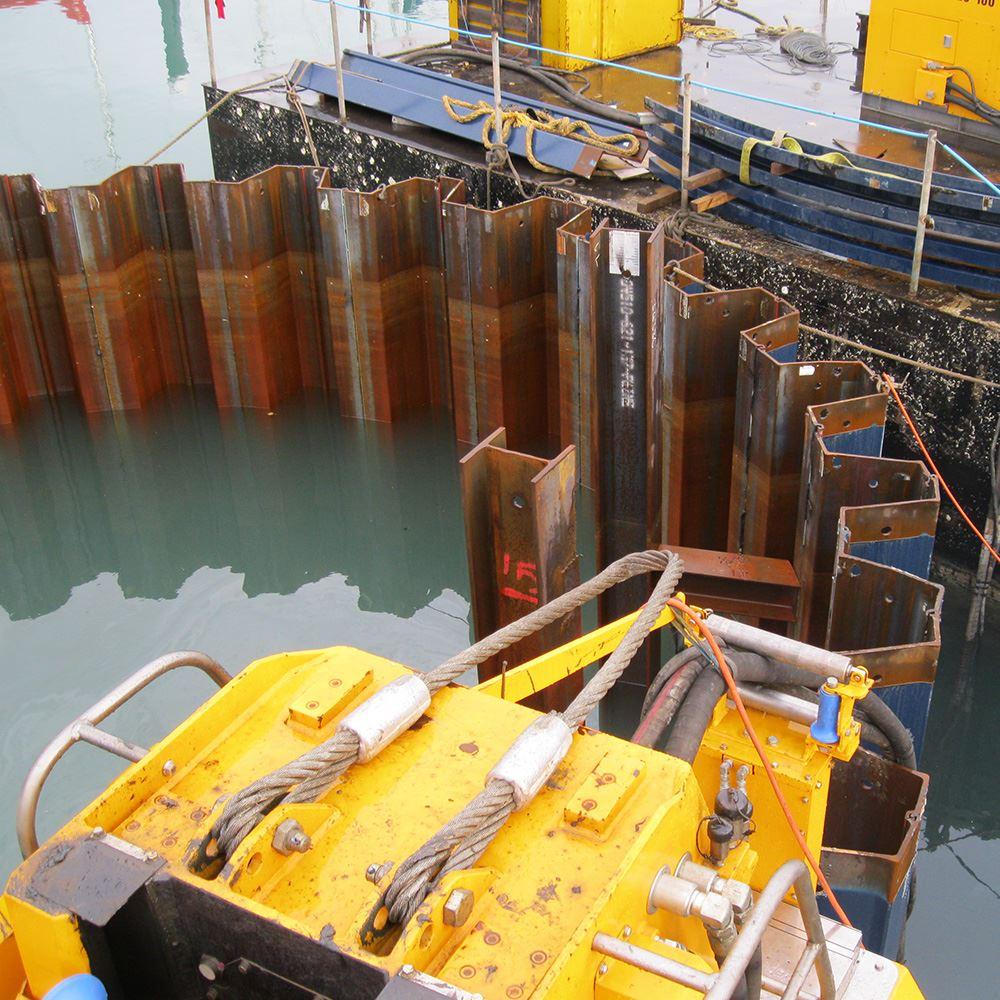

Case Study: Portsmouth

A PVE 2316 High Frequency Variable Moment vibratory hammer was used initially with a box pile clamp to extract the existing timber piles. It was then used to install and partially drive the sheet piles. There were concerns that vibration could cause settlement in the concrete support cradles, especially since the piles were in close proximity, so a Kowan Still Worker ZU-100 was used for the final drive to press the piles without vibration.

Case Study: Felixstowe

How can we help?

“Contact us today to discuss your piling plant requirements with our expert team.”

Scott